the whole world of manufacturing is continually evolving, driven by the necessity for greater precision, performance, and value-success. just one technological know-how that is definitely swiftly reworking industries is laser welding. As a number one Laser Welding Machine supplier, we have been witnessing firsthand the profound impression these devices are obtaining on present day producing procedures. This website put up explores the Main Added benefits and benefits of laser welding, demonstrating why it is starting to become an indispensable Software for organizations striving to remain competitive.

Table of contents:

Introduction to Laser Welding engineering

benefits of Laser Welders around Traditional Welding Methods

How Laser Welding devices enhance creation performance

Introduction to Laser Welding technological know-how

Laser welding is a fusion welding procedure that uses a targeted laser beam to affix products. The higher focus of Electrical power allows for deep, slim welds with nominal warmth-influenced zones. This precise Command minimizes distortion and damage to encompassing components. as opposed to common welding methods, laser welding may be used on the wider array of materials, together with dissimilar metals, and infrequently necessitates minimal to no filler product. The process is adaptable to automation, enabling for elevated velocity and regularity in generation. The Laser Welding equipment provider market is expanding quickly, driven from the expanding need for this multipurpose technological know-how.

benefits of Laser Welders around standard Welding solutions

in comparison to standard strategies like MIG or TIG welding, laser welding provides many essential pros. initial, the precision in the laser beam enables noticeably smaller sized and a lot more aesthetically pleasing welds. Second, the warmth-affected zone is noticeably reduced, minimizing distortion and preserving the integrity of the encompassing material. Third, laser welding is considerably faster, bringing about improved output throughput. Fourth, it can weld dissimilar metals a lot more efficiently, opening up new layout alternatives. last but not least, laser welding is extremely automatable, reducing labor expenditures and expanding consistency. This suite of benefits can make laser welding a powerful choice to conventional welding strategies to get a big selection of programs.

How Laser Welding Machines enhance creation Efficiency

Laser welding substantially increases output effectiveness in numerous ways. The pace and precision of the method allow for quicker welding cycles, resulting in bigger Laser Welding Machine supplier, manufacturing volumes. Automation abilities further more enrich effectiveness by reducing the necessity for guide intervention and reducing mistakes. The slim weld seams have to have significantly less put up-weld finishing, conserving time and assets. Additionally, a chance to weld dissimilar metals simplifies producing processes and lessens the necessity for numerous joining methods. by way of example, In keeping with facts from LatheGlobal, their fiber optic, drinking water-cooled laser welding (HW-2000W) tools demonstrates the Highly developed engineering driving this effectiveness revolution. The trustworthiness and repeatability of laser welding lead to constant products excellent and decrease scrap fees, even further boosting overall performance.

In summary, laser welding is revolutionizing modern-day manufacturing by furnishing unparalleled precision, speed, and efficiency. From aerospace to automotive to electronics, industries are significantly adopting laser welding know-how to gain a aggressive edge. for a Laser Welding Machine supplier, we've been committed to supplying reducing-edge answers that empower firms to transform their production procedures. for those who want to help your production capabilities and remain in advance of the curve, consider Checking out the many benefits of laser welding. the longer term of manufacturing is right here, and It really is becoming welded with lasers.

Alicia Silverstone Then & Now!

Alicia Silverstone Then & Now! David Faustino Then & Now!

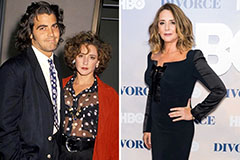

David Faustino Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now!